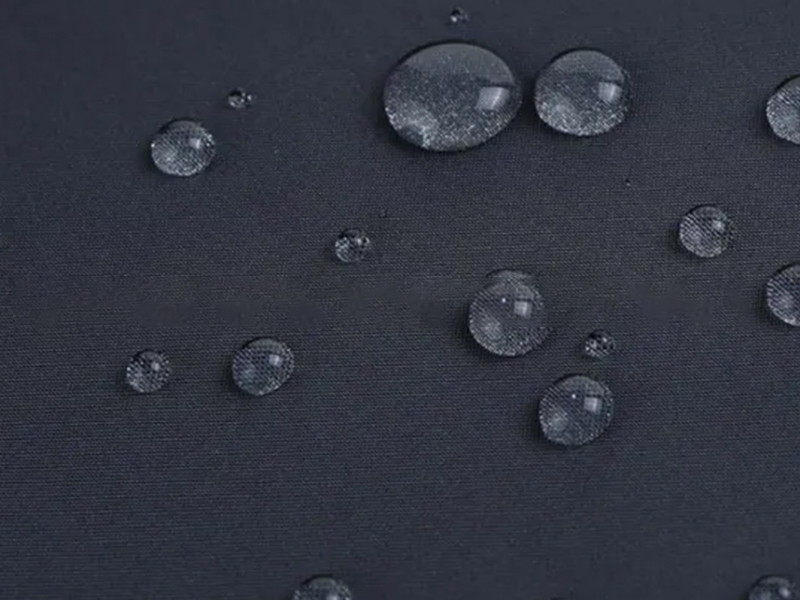

Raincoat fabrics generally have the following types:

1. Waterproof and breathable cloth

That is, the inner surface of the fabric is coated with a layer of waterproof and moisture-permeable paint, like the raincoats commonly used by police and mountaineers, with waterproof and breathable effects, but the price is high.

In short, Oxford cloth is more suitable for waterproof clothing, which is determined by its weave.

2. Cotton (nylon)

Silk gloss has good sensory effect, good strength and wear resistance, but it is easy to deform under the action of external force, so the fabric is prone to wrinkles during wearing.

3. Polyester

The biggest advantage of the fabric is that it has good wrinkle resistance and shape retention, but poor dyeability and poor moisture absorption and breathability.

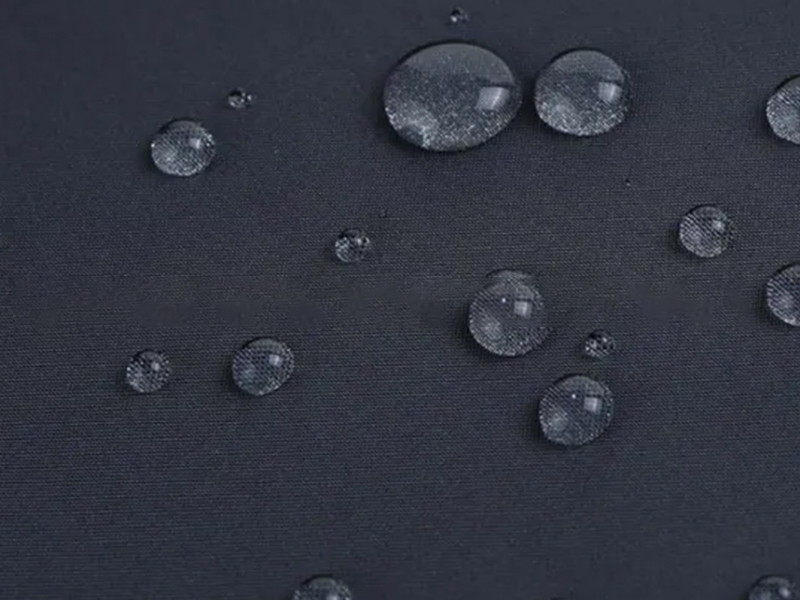

4. Oxford cloth

The product fabric obtained from cotton or polyester through a specific weaving method has the characteristics of easy washing and quick drying, soft hand feeling, good hygroscopicity, soft fabric color, soft cloth body, good air permeability, comfortable wearing, and two-color effect.

5. Application of waterproof and breathable fabrics

PTFF waterproof and breathable laminated fabric was first developed for the production of military uniforms, protective clothing, and then used in sportswear. The manufacturing of tents and other items, the current application fields are still expanding. For Air Force pilots, navy soldiers and special forces, the drop in body temperature caused by sudden immersion in cold water is one of the important factors causing casualties. The U.S. military has made waterproof and breathable clothing for Air Force pilots. Special anti-riot clothing for crew members and special forces performing sea, land and air operations. These garments provide up to 2 hours of protection in cold water at a temperature of 7 degrees and are light and comfortable to wear.

The main technical performance requirements of military raincoats are good waterproof and breathable function and light weight. PTFE microporous composite fabric not only solves the contradiction between breathability and waterproofing, but also reduces the weight of raincoats, thereby effectively reducing the load of soldiers.

For firefighting suits, the face is made of woven aramid fabric, the film is made of PTFE, the rico is made of warp-knitted aramid knitted fabric, and the drying agent is phosphorus-containing polyurethane. Improves the comfort of wearing protective clothing.

Military light tents require rainproof, flame retardant, anti-aging, etc., and PTFE film material has the characteristics of corrosion resistance, strong acid and alkali resistance, and aging resistance, so PTFE laminated fabric can be used.

Sleeping bags require warmth, breathability, light weight, etc. Based on the characteristics of PTFE microporous film laminated fabrics, a double-layer structure is adopted, the outer layer is nylon fabric, and the inner layer is Pwu FE film. There is no risk of hypoxia and carbon monoxide poisoning when this sleeping bag is used.

Because PTFE material has extremely different chemical corrosion resistance and flame retardant properties, coupled with the microporous structure of the film, it has superior waterproof (liquid) breathability, so it has become an ideal material for the development of nuclear, biological and chemical protective clothing.

PTFE waterproof and breathable laminated fabric can not only meet the wearing needs of people in harsh environments such as severe cold, rain, snow and strong winds, but also meet the requirements of people's daily life for raincoats and shoes, and has broad application and development prospects.

The focus of the research and development of the last PTFE waterproof and breathable laminated fabric is to reduce costs and make efforts in the direction of making the fabric lighter, more comfortable and more multifunctional.